Control reactions precisely and cost-effectively with reliable devices that fit your deck and your workflow

Inheco makes lab automation products that are versatile, reliable and easy to use. Our on-deck devices help you mix liquids and manage heat to control reactions precisely and cost-effectively. Whether your lab is already automated or just starting out, our small, adaptable, SiLA-compliant devices fit easily into your deck and your workflow.Choose from our range of standard products or OEM products customized to the specific needs of your automated liquid handling platform. Built and quality control checked in-house to industry-leading standards that our customers in big pharma, biotech, diagnostics and research & academia rely on.

About Inheco

On Deck Thermal Cycler - ODTC®

Fast, uniform results from a thermal cycler that fits easily onto your deck.Read more

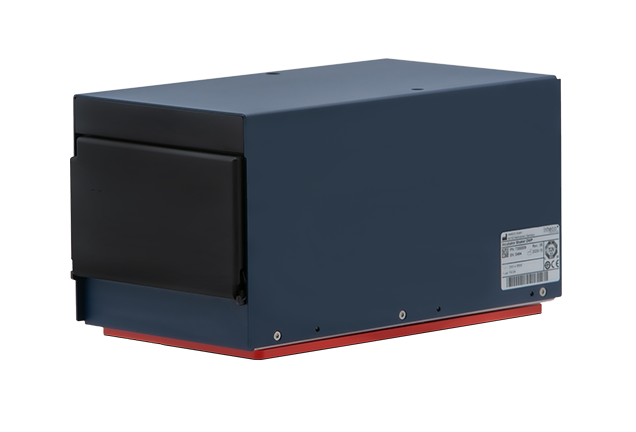

SCILA CO2 4-Position cell incubator

Maximum variability of cell incubation parameters in minimal space on your deck.Read more

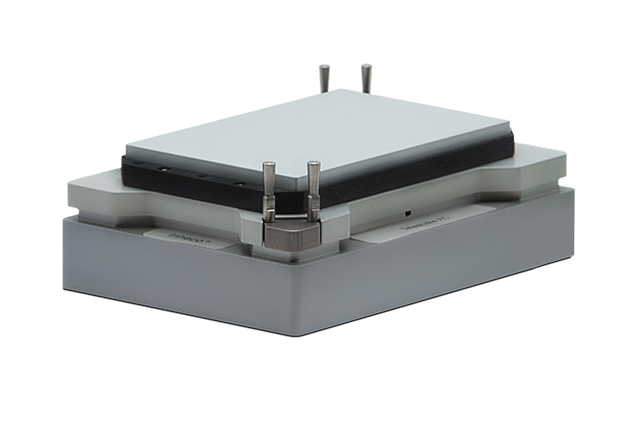

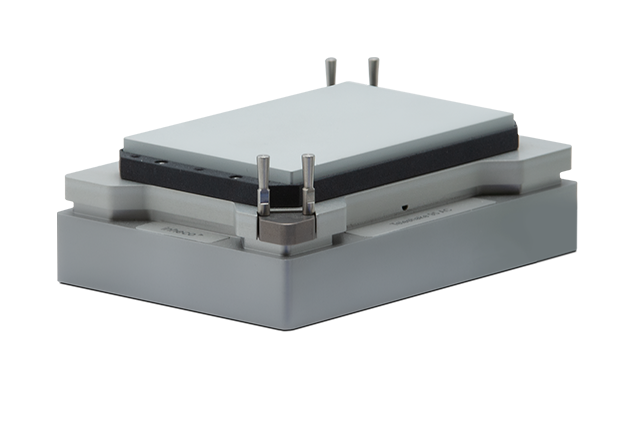

Teleshake 95 AC

High performance compact heater-shaker with secure fixing for variable plates.Read more