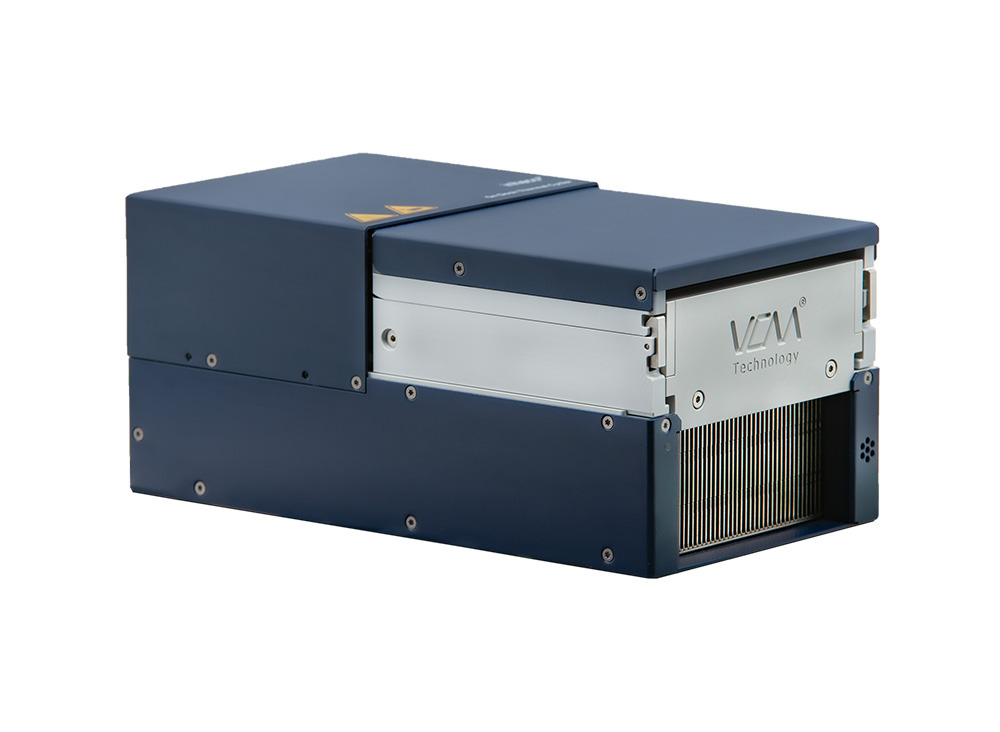

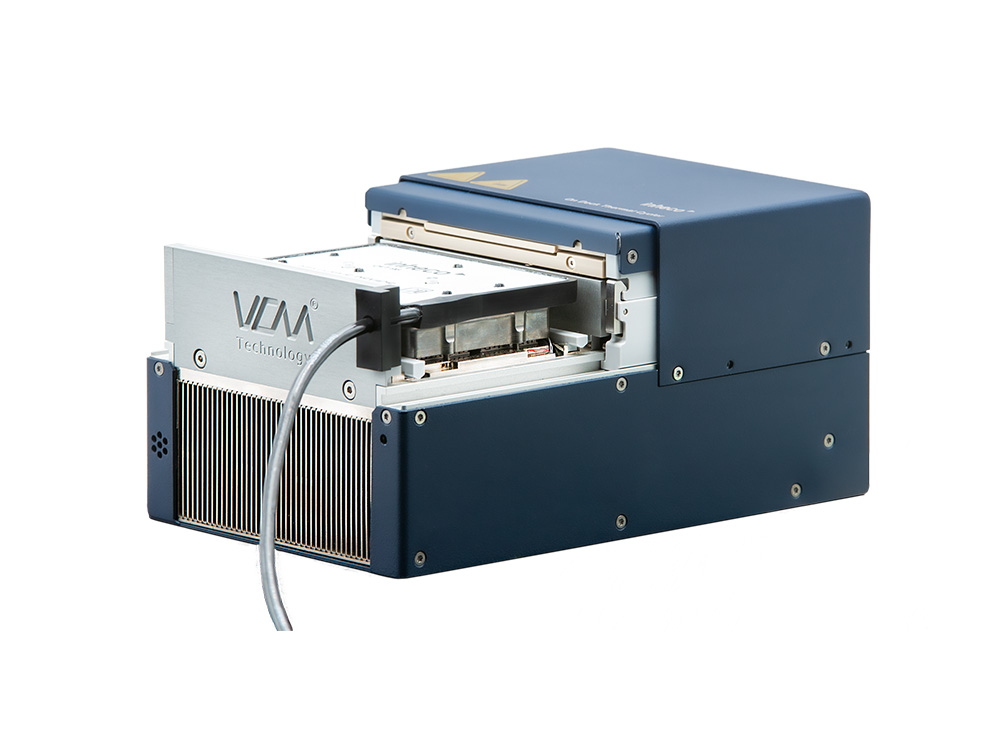

On Deck Thermal Cycler - ODTC®

Fast, uniform results from a thermal cycler that fits easily onto your deck

The Inheco ODTC® delivers rapid, accurate, and cost-effective sample processing for every sample, every time.Thermal cyclers have become an essential tool in genomics, molecular biology and biotechnology. They’re used for modifying and amplifying genetic material, including for PCR, and in NGS (Next Generation Sequencing). To earn a place in your automated deck, a thermal cycler needs to deliver rapid, reproducible results that are uniform across the entire sample range for the whole run, whilst taking up minimal deck space. Labs, assay owners and integrators choose the Inheco ODTC® because it delivers the best results and does everything they need.

FAST, UNIFORM, ACCURATE HEATING

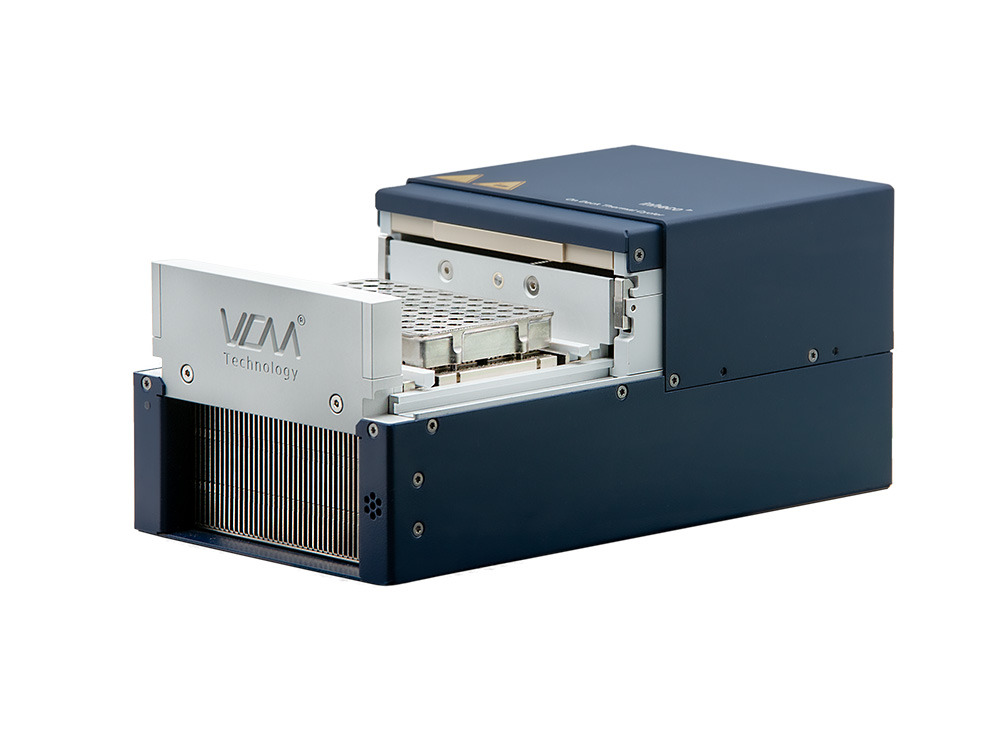

Thanks to our patented Vapor Chamber Mount® (VCM®) technology the ODTC® delivers reliable results, superfast, every time. With near-instantaneous, precise heating and cooling and transition to plateau temperature, the VCM® also guarantees uniformity across the entire plate, including unequally filled plates or wells. The ODTC's® horizontal lid can be opened automatically at any point in a run, with negligible effect on temperature, ensuring problem-free 24/7 automated operations.

SMALL AND FLEXIBLE

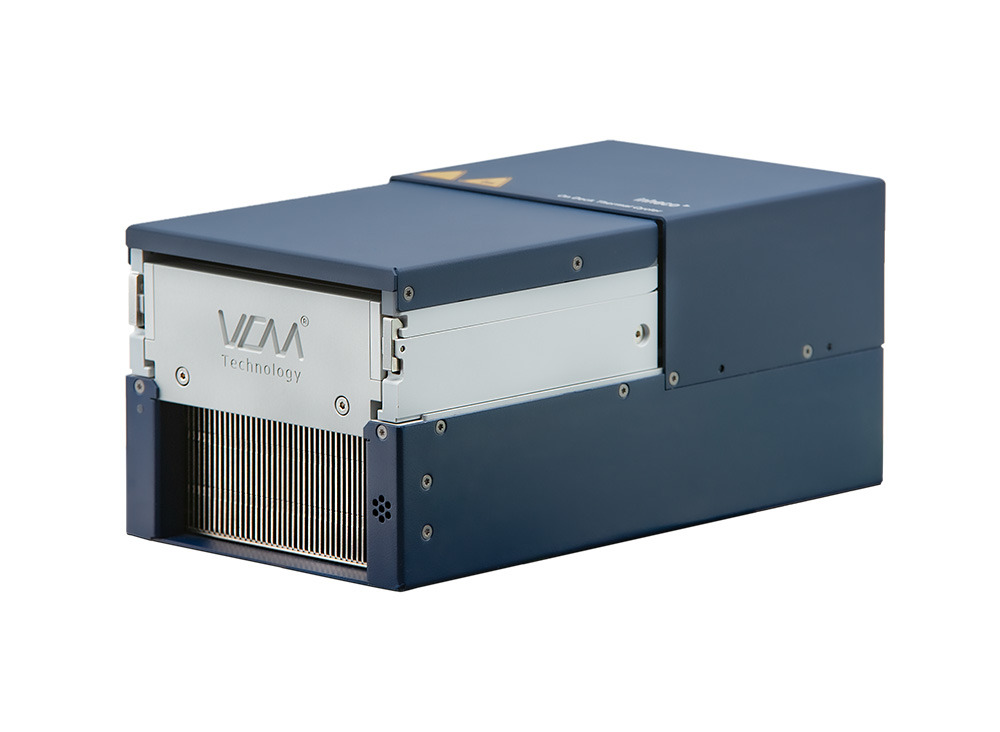

The ODTC® takes up minimal space on your deck with a footprint on just two standard microplates (124 mm H x 157 mm W x 248 mm L). The ODTC® is available with different ventilation configurations for flexible positioning, you can place 4 ODTC’s® in a square with no issue or problem with ventilation.

EASY TO INTEGRATE

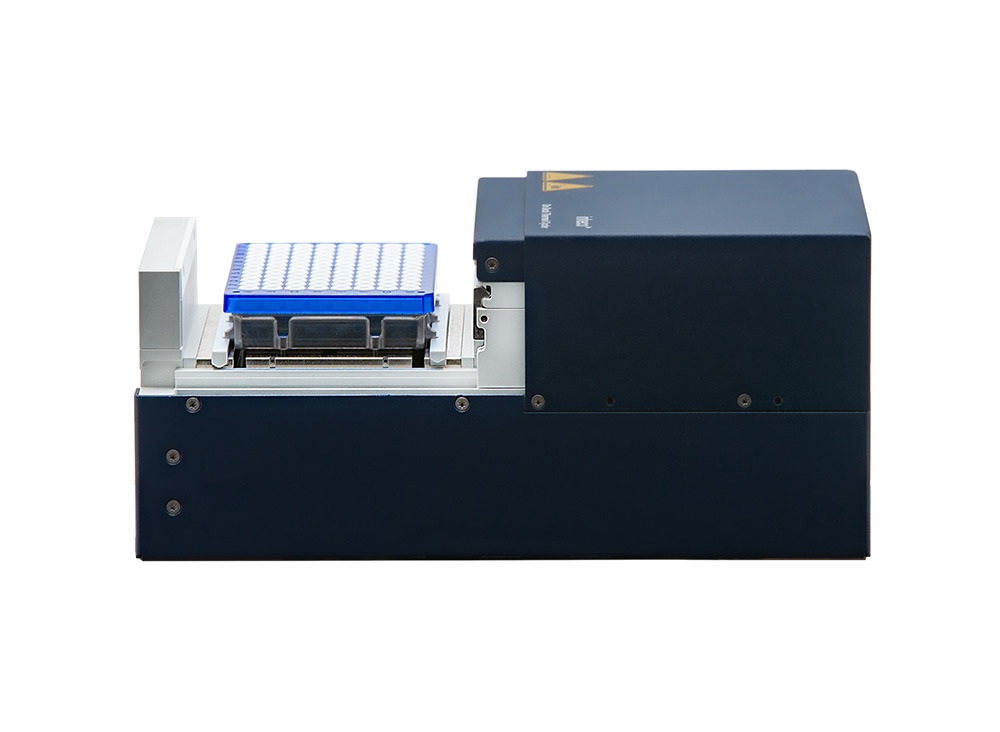

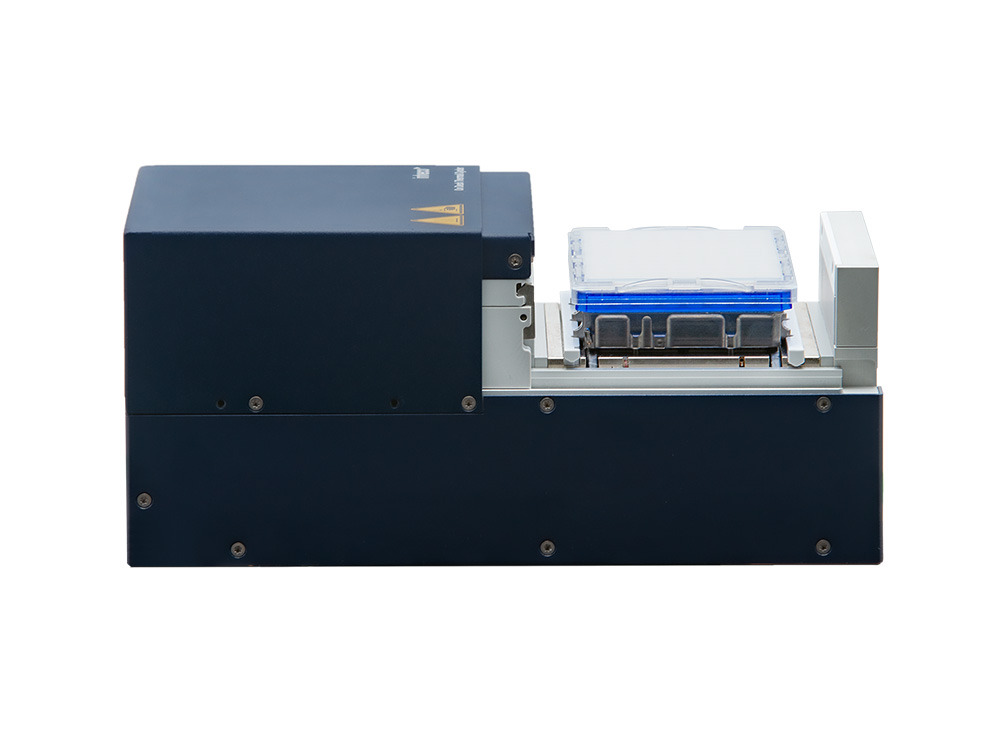

The ODTC® has a SiLA-compliant interface that integrates easily into automated workflows, and almost every deck, without modifications. It’s already in use by the world’s leading deck manufacturers and is easy to integrate with new decks. And whether you choose the 96-well or 384-well version, in standard size or taller XL size, it’s compatible with all standard PCR plates and lids.

UNRIVALLED CONFIGURATIONS

The ODTC® is available in multiple configurations – at 1st glance, the range of options can be confusing. The flexibility can be split into 3 distinct areas:

- Well Plate Type

We offer the ODTC® configured for either 96 well PCR plates or 384 well PCR plates - Plate Height

We offer the ODTC® in standard size for standard/low profile 96-well PCR plates and XL size for high profile 96-well plates - Ventilation

We offer 4 different ventilation directions – downwards, rearwards, left & right

RELIABLE AND SUPPORTED

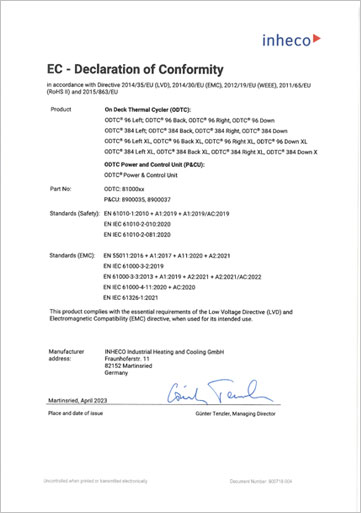

Every Inheco device is designed, engineered and made in Germany and undergoes rigorous quality control before delivery. It comes with a global two-year warranty and full customer service including remote support, diagnostic and servicing options that focusses on minimizing operational downtime.

Get a Quote