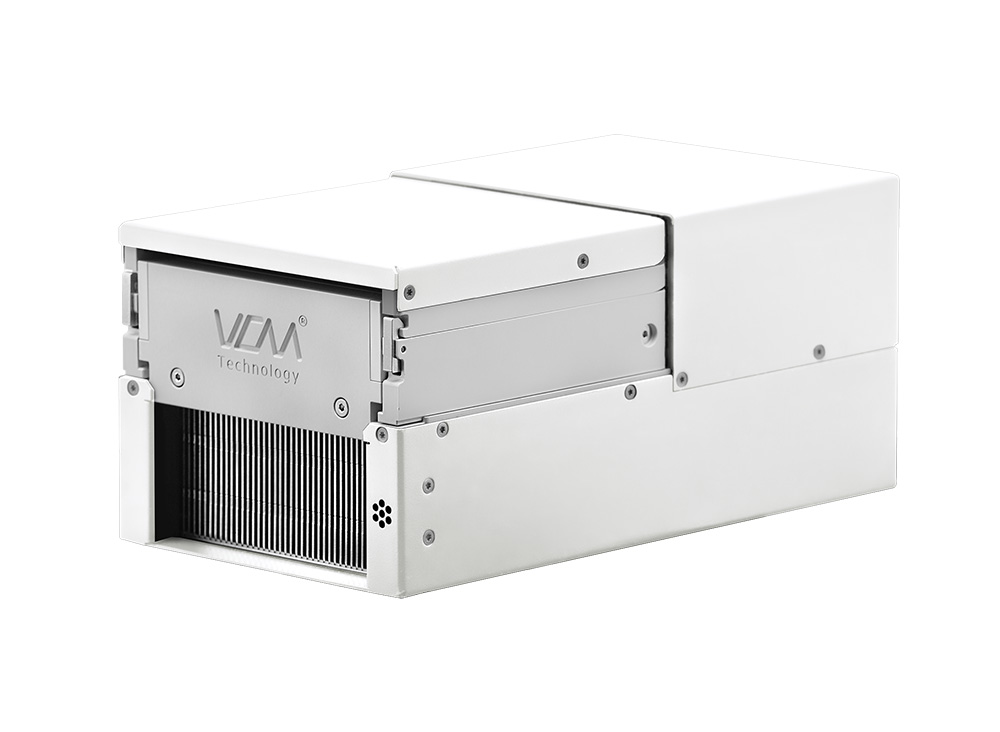

OEM Solutions

Inheco expertise for your customers

Our designers, engineers and thermal management specialists are available to create devices designed for your business needs, or to meet the requirements of your customers. We build customized devices, supply OEM products and offer thermal management consulting.Developing OEM products with Inheco

Work with Inheco and take advantage of our R&D capabilities and development tools to develop new products for your customers.R&D capabilities:

- Development of thermal management concepts

- Analytical calculations, software simulation, 3D CAD

- Development of electronic hardware, soft- and firmware

- Prototyping (feasibility, functional and pre-series samples)

- Experiments and tests (performance, lifetime and safety)

- Risk analysis and risk management

- Integration of strategic suppliers for critical components

- Documentation (R&D project documentation, product documentation)

- Product transfer from R&D to series production

- Verification and validation (PLV, verification and validation of tools and tests)

Development tools:

- 3-D design software (Solid Works)

- Thermal, fluid dynamical and mechanical simulation (Flowtherm, Cosmos Works)

- Test rigs

- Climate chamber tools

- Infrared camera.

Producing OEM devices with Inheco

Once designed, developed and approved. Your products will be manufactured, checked and delivered to the same high standards as all our Inheco branded products, including:Manufacturing

Your products are made in our modern, specialist factory

- Skilled manufacturing personnel for electronic and mechanical production

- Semi-automated assembly tools

- Route cards for every product

- Assembly instructions for every product

- Calibrated production tools

- ESD controlled environment

- Continuous training and skill improvement

We work to ISO 9001:2015 certified quality management standards

- Inspection of incoming goods

- Inspection during production/assembly process

- Burn-in tests for specific OEM products

- Calibration and adjustments

- 100% Thermal end test (automated and semi-automated)

- Lifetime tests

- Development of test tools (measurement heads, laser rpm counters)

- QC analysis and documentation (QC database, test reports)

- QC Audits for key suppliers

- Continuous improvement processes

- Safety and transport tests

We can customize logistics to your requirements

- Tailor-made packaging, transport, customs, custom labelling

- Serial number tracking

- ERP based logistics, supporting various inventory control methods

- Frame contracts, safety stocks, JIT